T: 905-664-8661

info@cuttingtoolpickers.com

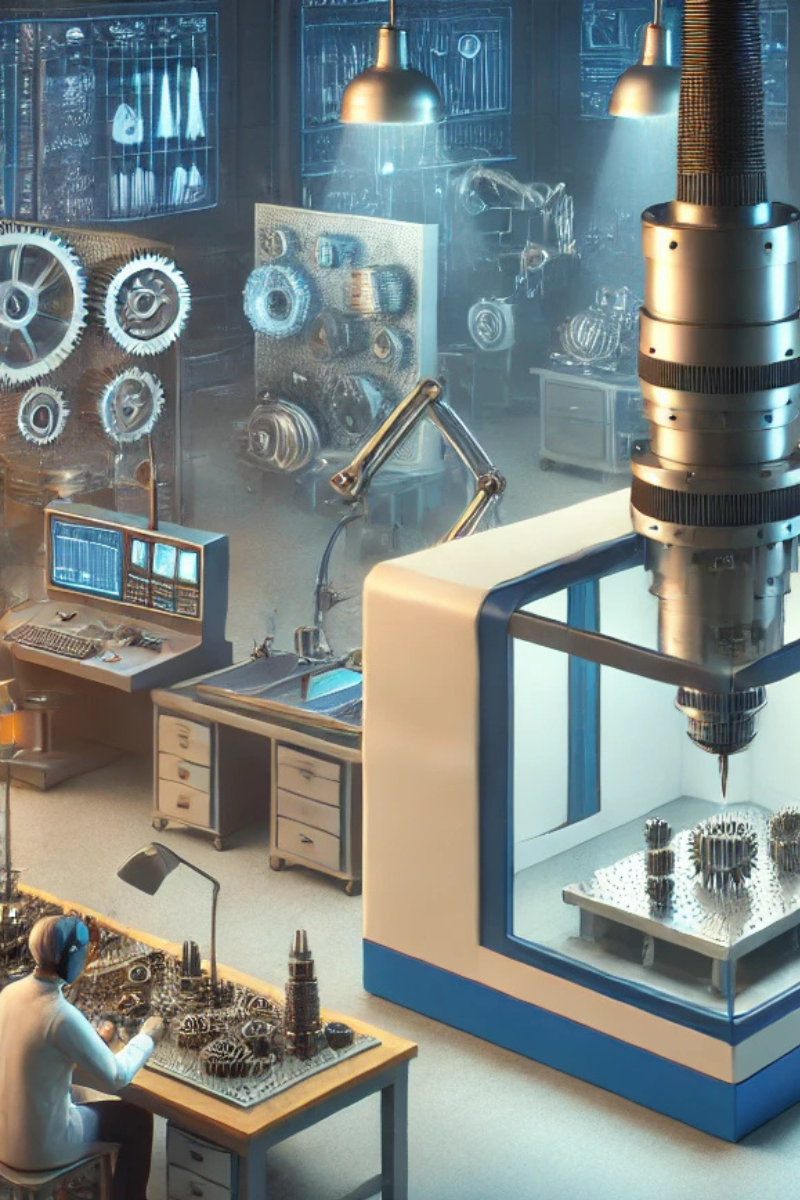

Diversifying Your Revenue Streams: Niche Markets for Machine Shops in 2025

The manufacturing industry is evolving rapidly, and for machine shops, diversification is no longer optional—it’s a necessity. With supply chain disruptions, changing customer demands, and new technological advancements, machine shops must explore niche markets to remain competitive and profitable. Expanding into specialized industries can not only provide stability but also unlock new revenue opportunities.

Here’s a look at some of the top niche markets for machine shops in 2025 and how they can tap into these opportunities.

1. Aerospace and Defense Manufacturing

The aerospace and defense industries have stringent requirements for precision machining, making them a lucrative market for machine shops that can meet their high standards. The demand for lightweight, high-strength materials like titanium and carbon composites is increasing, and CNC machining plays a critical role in their production.

Opportunities:

-

Manufacturing aircraft components such as brackets, engine parts, and landing gear.

-

Producing precision parts for defense applications, including firearms, military vehicles, and communication equipment.

-

Obtaining certifications like AS9100 to qualify for aerospace contracts.

2. Medical Device Manufacturing

The medical industry is experiencing rapid growth, with increasing demand for precision-machined components used in medical devices, implants, and surgical instruments.

Opportunities:

-

Producing custom orthopedic implants, prosthetics, and dental components.

-

Machining surgical tools with high accuracy.

-

Manufacturing small, complex components for diagnostic equipment.

-

Meeting FDA and ISO 13485 compliance standards for medical manufacturing.

3. Electric Vehicle (EV) and Battery Production

With the global push toward electric mobility, machine shops can capitalize on the demand for precision components in the EV and battery industry.

Opportunities:

-

Producing battery enclosures, cooling systems, and structural components for EVs.

-

Manufacturing specialized connectors and terminals for lithium-ion batteries.

-

Partnering with EV startups and manufacturers looking for reliable machining partners.

4. Renewable Energy Sector

As the world shifts toward sustainable energy, machine shops can tap into the growing need for components used in wind, solar, and hydroelectric power generation.

Opportunities:

-

Machining turbine components for wind energy.

-

Producing parts for solar panel mounting systems.

-

Manufacturing precision components for hydroelectric turbines.

5. Robotics and Automation

The rise of automation in manufacturing has increased the demand for precision-machined parts used in robotics and industrial automation systems.

Opportunities:

-

Producing custom robotic arms and automation system components.

-

Manufacturing gears, shafts, and housings for robotic applications.

-

Working with automation integrators to supply precision components.

6. Custom Tooling and Prototype Development

Many industries require specialized tooling for manufacturing, testing, or product development. Machine shops with expertise in rapid prototyping and custom tooling can benefit from this demand.

Opportunities:

-

Producing custom jigs, fixtures, and dies for manufacturers.

-

Offering rapid prototyping services for startups and R&D teams.

-

Collaborating with engineering firms to develop innovative solutions.

7. High-End Automotive and Motorsport Components

Performance vehicles and motorsports require specialized machining for custom engine parts, suspension components, and lightweight materials.

Opportunities:

-

Machining custom parts for race cars and performance vehicles.

-

Producing aftermarket engine components and tuning parts.

-

Partnering with automotive restoration businesses.

8. Firearms and Sporting Goods Manufacturing

The demand for precision-machined firearms, optics mounts, and sporting equipment continues to grow, making it an attractive niche for machine shops.

Opportunities:

-

Manufacturing firearm components such as barrels, triggers, and scope mounts.

-

Producing parts for archery, cycling, and outdoor sporting goods.

-

Meeting regulatory requirements for firearm production.

9. Food Processing and Packaging Equipment

The food industry relies on high-precision, sanitary components for processing and packaging equipment.

Opportunities:

-

Machining stainless steel components for food processing machinery.

-

Producing precision parts for automated packaging equipment.

-

Meeting sanitary compliance standards for food production.

10. 3D Printing and Hybrid Manufacturing

Machine shops can expand their services by integrating additive manufacturing (3D printing) with traditional machining for more efficient and cost-effective production.

Opportunities:

-

Providing hybrid manufacturing services that combine 3D printing with CNC machining.

-

Producing low-volume, complex geometries for various industries.

-

Offering post-processing and finishing services for 3D-printed parts.

How to Successfully Enter a Niche Market

Breaking into a new market requires careful planning and strategic investment. Here are some steps machine shops can take to diversify effectively:

✅ Conduct Market Research – Identify industries with growing demand and evaluate their machining needs.

✅ Upgrade Capabilities – Invest in advanced equipment, software, and certifications to meet the industry standards.

✅ Develop Strategic Partnerships – Build relationships with suppliers, customers, and industry leaders in the target niche.

✅ Enhance Marketing Efforts – Optimize your online presence, showcase expertise in niche markets, and leverage digital marketing strategies.

✅ Train Your Workforce – Ensure employees have the skills and training required for specialized manufacturing processes.

Conclusion

Diversifying into niche markets allows machine shops to stay resilient, increase revenue, and future-proof their business. By targeting high-demand industries such as aerospace, medical devices, EV manufacturing, and robotics, machine shops can secure long-term success in an ever-changing landscape.

Looking to expand your capabilities? Cutting Tool Pickers offers high-quality tools to support precision machining across industries. Explore our catalog today and take your machine shop to the next level!

Leave a comment