T: 905-664-8661

info@cuttingtoolpickers.com

The Basics of Laydown Threading

As one of the few cutting tool brands that mine their own raw carbide, Ceratizit's strength in indexable tooling starts from the ground up. Their product line features a full range of threading inserts with pitch and grade options to cover each application.

In this blog post, we cover the basics of laydown threading:

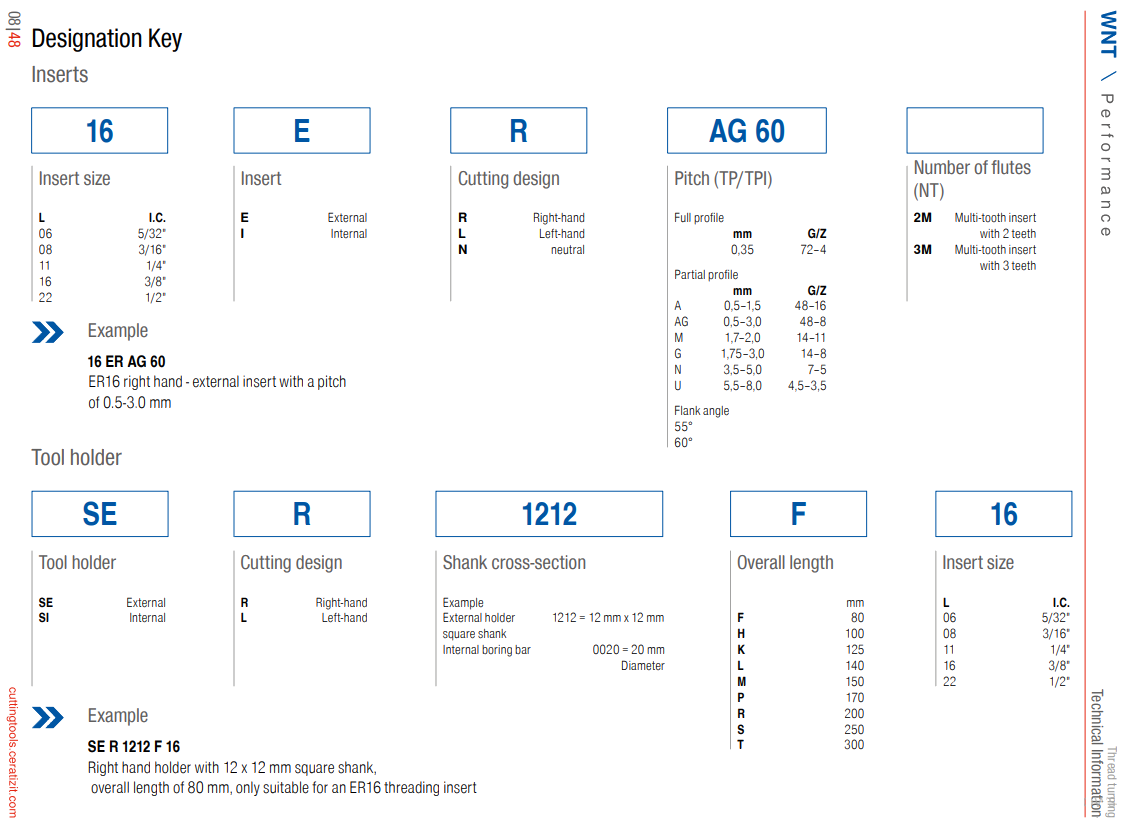

- Threading insert identification

- Threading profile selection

- Insert wear troubleshooting

Threading inserts are available in either full profile or partial profile configurations. The differences between full profile and partial profile inserts are outlined below.

Profile Types

- Highest quality thread

- No burr formation

- Longer in-part tool life

- Insert can only be used on a single pitch

- A single insert will cover a range of thread pitches

- Reduced stock requirements due to the ability of a single insert to cover multiple applications

- Core diameter must be premachined to the finished size

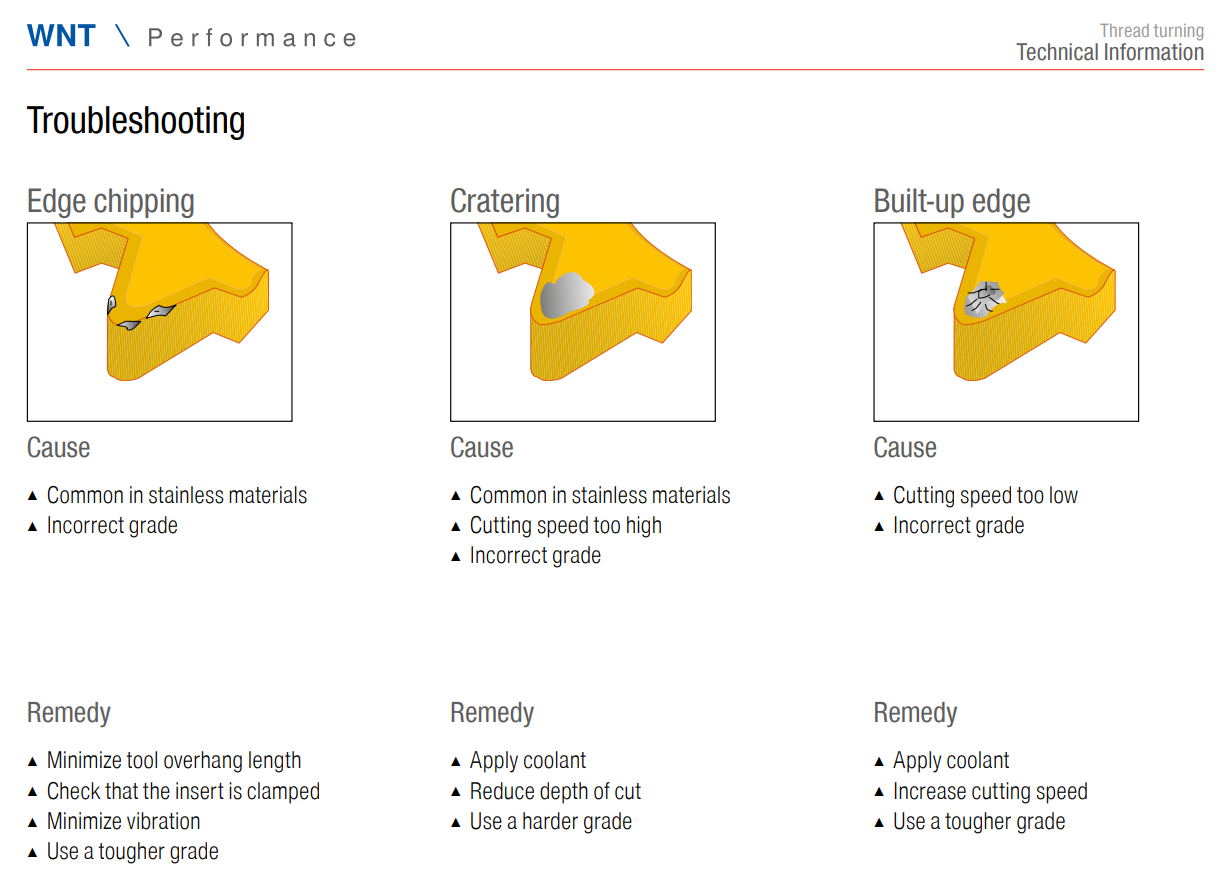

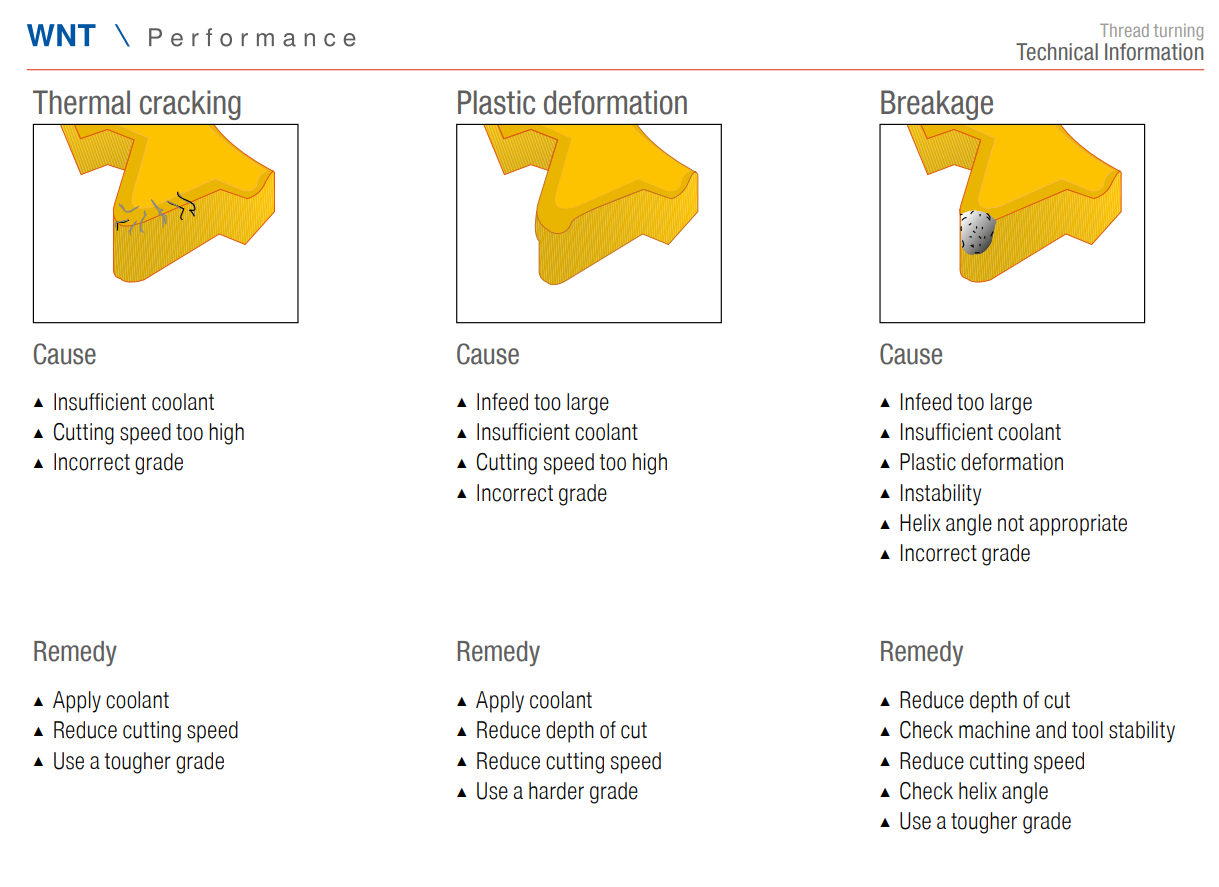

Common Causes of Wear

What causes premature insert wear? Here are a few troubleshooting tips on identifying and treating the root causes of insert wear:

For any additional information on Ceratizit's Indexable line, contact our staff at:

Info@cuttingtoolpickers.com

905-664-8661

Info@cuttingtoolpickers.com

905-664-8661

Leave a comment